In 1993, Glaub Farm Management was started out of the home I had just purchased. The office consisted of a desk in the living room and two interns working in the front bedroom. My wife Laverne and I recently moved out of that house and could not believe all that we had added to it during the past 25 years. It is also hard to believe the changes to Glaub Farm Management during that time.

We have gone from one manager with part-time staff at an in-home business to two managers, one appraiser and three staff members at an office purchased in 2005. In addition, we normally have an intern from ASU working in the office. Our computer system began as three individual computers with Lotus Symphony and an accounting package. Today, we have an eight-computer network system with the ability to connect remotely to both laptop computers or iPads.

Although our software system has more than doubled, we continue searching for a better accounting system capable of both business analysis and agronomic data collection and processing. We are trying three different mapping programs this year, and additional programs were added for the appraisal section of our business. We even use software for multi-tract land auctions. The area of information collecting, processing and managing is a constant challenge for us and one in which we are constantly seeking ways to upgrade.

It is hard to believe that when we started a bag cell phone was our main way to communicate when out on the farms. Email was not readily available until the very end of the 1990s, but its adoption was a major improvement over the old fax systems. Today we text, instant message and use other electronic forms of communication. It amazes me that I can now communicate with a client in another country instantaneously. On the other hand, we still have clients in the states for whom it may take a week to receive our information by postal mail.

In most situations, though, we depend more on texts and emails to contact clients and farmers. Instead of playing phone tag, we can send messages electronically at any time of the day or night. This also helps address different time zones or taking up time when people are busy with their day jobs. They can read the message after hours or at their convenience and allow time to process the information.

We continually work to improve our communication with our clients, input providers, consultants and operators. When searching for a new operator, we no longer simply look at the operator but the entire team with whom he or she works. The increasing complexity of farming operations requires multiple sources of information to answer questions and make management decisions.

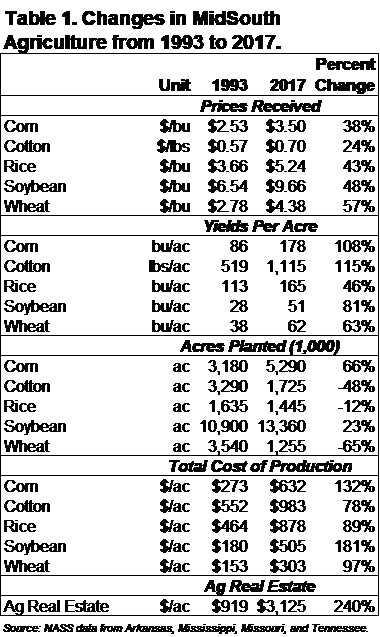

Looking back over the last 25 years, the trends affecting such decisions provide interesting insight. Table 1 below compares the prices, crop yields, planted acres, cost of production and land values from NASS for 1993 and 2017 for the Mid-South. Prices have not kept up with increasing costs. Our major income crops of cotton and rice in 1993 are grown on fewer acres today. Technology has changed the production and costs of production of the various crops. Cotton has seen a 115% increase in yields, but price only increased 24%, while input costs increased at an even greater rate. This cost-price squeeze put pressure on cotton acres. Since most production costs are borne by operators, they are less willing to grow cotton. The slow increase of rice yields and increasing energy costs has caused rice acres to drop. This is particularly true in high irrigation cost areas.

On the other hand, zero-grade production has increased rice production in marginal flood prone areas replacing late planted soybeans. Operators learned that the cost of production on zero-grade land is considerably lower than other rice production practices. The reduction of tillage requirements on this type of acreage provides the operator with greater flexibility to get a rice crop planted in flood zones.

Improved technology in corn and soybean production has increased acres of both crops in the Mid-South. The introduction of Roundup Ready soybeans and corn made average farmers look great at controlling weeds. Roundup made farm weed control simpler. Changing from group 5 and 6 soybeans to group 4’s increased soybean yields by approximately 10 bushels. This higher yield has put pressure on wheat acres. The reduced yields of double-crop soybeans basically made full season soybeans more profitable than wheat/double-crop soybeans. The improved yields of corn and soybeans led to an increase of acreage, which was compounded by the new high prices of both during 2012. Rice and cotton did not increase enough to keep acres.

Cotton did increase acreage during the 1990s with the introduction of the Boll Weevil Eradication Program, which increased cotton yields by about 500 pounds per acre. A shortage of cotton in China pushed cotton to over $1 per pound. The problem was we over produced and built up inventory to supply two years of cotton demand. This led to depressed cotton prices during the high corn and soybean prices in 2012. Many cotton farmers sold their equipment and went into grain farming. Cotton infrastructure also was closed. Our area lost a considerable number of gins and warehouses. The market stress from very high cotton prices to very low prices also put many of our cotton buyers out of business.

Industry changes and market trends have naturally led to changes in our business. When Glaub Farm Management started, the main focus was converting dryland production to irrigated. Drainage was and still is a major issue in our region. Today, we still work in these areas—we just focus on different subareas, such as methods to reduce our dependence on ground water. This is accomplished by more efficient use of ground water and adding surface water to our irrigation systems. Surface water also lowers the energy costs in many areas. Our objective is to have sustainable irrigation available for future generations.

Fertility is also a growing area of interest. As new technology has improved production of various crops, the demands on the soils for nutrients has also increased. It appears producers are leaving yield on the table by not having enough nutrients available in the soil. At GFM, we are looking at ways to increase nutrient levels, such as litter, cover crops and other new technology. When you consider what is taken out of the soils by today’s yields, more has to be put back in. One of our farms has produced over 100-bushel soybean yields—the level of nutrients removed by this type of crop is totally different than when I started. Our objective is to improve nutrient stewardship by using the right sources, right rates, right timing and placing nutrients in the right location.

Such stewardship requires taking advantages of changes in our region, including the use of chicken litter. PECO has added an entire broiler unit in Pocahontas, Arkansas, establishing the need for 600 new chicken houses which will have litter for sale. We have worked for over 10 years in areas and gathered information on the use of chicken litter. The 100-bushel soybean production mentioned above was on a farm with a long-term litter use. On this farm we were even able to get litter with high calcium levels and substitute for lime needs.

Other changes involve GPS systems that are providing more information on the farms than I ever dreamed. In fact, we often experience data overload. The adage “garbage in, garbage out” fits within farming too. The data collected must be useful to make sound management decisions. GPS has taken us from managing by the field as one unit to managing by multiple zones within a field. We no longer treat the entire field with lime. Instead, we lime the field zones when soil tests recommend application. An example of excessive data is a zone smaller than a five-acre area that may need lime. This is not an economical area to treat by itself. Normally we purchase lime in 20-ton truck loads. Since a two ton per acre requirement on five acres is less than a truckload, you have to look at alternative methods or wait until other zones require lime to make an economical application.

In the future, our ability to combine information from all of the new resources that are now available is going to provide for increased profits. We hope to receive better information from past production to build improved management systems in the future. Change is going to continue, and it appears this will be both faster and more complex. The end results hopefully will provide for sustainable farms.

I also see more information being required in the future in our real estate side of the business. As more information becomes available at affordable costs, providing the information on land will become the standard. You will not be able to say the farm is a top producer. You will have to provide the information that proves the farm is a top producer. It also appears the market for our products is going to require more information on the products we produce. The younger generation is interested in where and how their food is produced. This will open a whole new area of information to track. It appears that opportunity will continue to be in our future.

25 years have flown by. As I reflect on the changes that have occurred in our business, one vision remains the same as the day we opened—providing top-notch service to our clients. Improving our land services has always been and will continue to be our focus. We added an appraisal division headed by Houston Matthews in order to enhance our service to all clients. Valuations will also provide data for our management clients to improve asset analysis, and our real estate brokerage will have access to a more accurate and complete sales database.

We want to thank all of our clients for entrusting us with your business. We also want to thank friends, families and business associates for your support through our 25-year journey and into to the next 25.

By Ted L. Glaub